Instasim: Streamline Robotics with Cloud-Based Simulations

Discover the power of accurate RCS-based simulations to optimize your industrial robotics applications.

About Instasim

Instasim, currently in its advanced prototyping stage, is a groundbreaking web service designed to revolutionize the world of industrial robotics. Born from a visionary research project, Instasim offers unparalleled simulation accuracy through the use of sophisticated Robot Controller Simulation (RCS) modules. These modules, developed by the Robot Manufacturers, enable precise emulation of industrial robot programs. This unique capability ensures that our simulations closely mimic real-world operations, allowing for meticulous optimization of robot paths and speeds. Tailored primarily for B2B applications, Instasim is an ideal partner for industries seeking to enhance their robotics programming and operational efficiency, particularly in sectors like automotive and additive manufacturing. Our service not only aids in verifying the feasibility of prescribed robot speeds and motions but also paves the way for seamless integration into existing software environments, promising a new era of efficiency and accuracy in industrial robotics.

Features and Benefits

Precision and Accuracy

With RCS-based simulations that replicate real-world conditions, Instasim ensures high precision in robot simulation. This accuracy is crucial in industries where differences in application speed or cycle time can lead to significant quality issues or operational setbacks.

Manufacturer-Agnostic Compatibility

Instasim stands out with its universal applicability across different robot brands. Currently supporting KUKA and ABB robots, our platform is designed with a standardized interface for RCS modules, enabling future expansions to virtually all industrial robot manufacturers.

Versatile Application

A standout feature of Instasim is its capability to operate RCS modules independently from the client's local machine. This innovative approach allows for greater flexibility in application, as it removes the need for local installation and maintenance of RCS modules.

Instasim in Action:

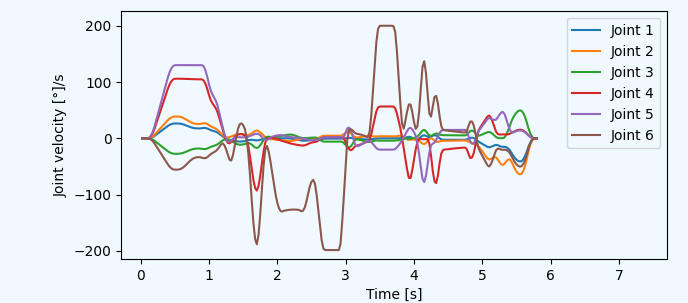

Cycle Time Optimization in Process Simulate

This demonstration showcases our Process Simulate plugin in action. By providing immediate feedback on robot path changes, it significantly reduces the time spent on waiting for foreground robot simulations that block the user interface.